For businesses dedicated to manufacturing and fabrication, precision is often the difference between success and failure. In industries such as automotive and aerospace, which rely heavily on efficient pipe-cutting services to meet their production needs, CNC pipe-cutting systems have been a game-changer. Companies that have invested in these advanced systems have enjoyed significant improvements in several crucial areas because of their versatility.

The Evolution of Pipe Cutting Systems

Traditional methods of pipe cutting, such as manual cutting or using outdated machinery, were not only time-consuming but also prone to inaccuracies. These methods often resulted in uneven cuts, leading to material wastage and compromising the quality of the final product. Moreover, the safety of workers was also a concern, as manual cutting processes involved significant risks.

Enter CNC Pipe-Cutting Systems

CNC pipe-cutting systems have revolutionized the way pipes are fabricated. These automated systems are equipped with advanced software that allows for precise cutting based on predefined specifications. By utilizing CAD (Computer-Aided Design) models, CNC pipe-cutting systems can produce intricate cuts with unmatched accuracy.

How CNC Pipe Cutting Systems Work

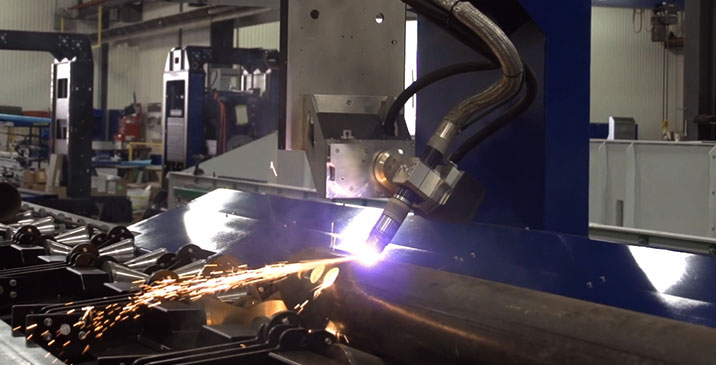

A CNC pipe-cutting system operates by first importing a CAD model of the desired pipe design. The software then generates a cutting path based on the specifications provided. The pipe is securely clamped in place, and the cutting head, equipped with a high-powered plasma or laser cutter, moves along the predefined path, cutting the pipe with precision. This automated process eliminates the need for manual intervention, resulting in faster production times and superior accuracy.

Benefits of CNC Pipe-Cutting Systems

Fabrication shops that utilize CNC pipe-cutting systems enjoy an array of advantages over their competitors, including:

- Improved productivity – CNC pipe-cutting systems can significantly increase productivity by reducing cutting times and minimizing material wastage. This allows businesses to meet tight deadlines and fulfill large orders more efficiently.

- Enhanced safety – With automated cutting processes, the risk of accidents and injuries associated with manual cutting methods is greatly reduced. CNC pipe-cutting systems prioritize worker safety and are an ideal choice for manufacturing environments.

- Cost savings – By reducing material wastage and increasing efficiency, CNC pipe-cutting systems can lead to substantial cost savings for businesses. Additionally, the precision cuts produced by these systems result in higher-quality end products and reduce the need for rework.

- Versatility – CNC pipe-cutting systems are incredibly versatile and can accommodate a wide range of pipe sizes and materials. This versatility makes them suitable for a variety of industries and applications.

The Go-To Choice for Plasma CNC Pipe-Cutting Machines

If a CNC plasma cutting system sounds like the perfect fit for your pipe-cutting needs, look to Machitech. We’ve been producing advanced plasma cutting systems for more than 15 years and can meet the diverse needs of clients from any industry. Our custom CNC pipe-cutting systems produce reliable results, and our MachiCare Preventive Maintenance Program will ensure that your system stays online.

Contact Machitech today if you’d like additional information about the CNC pipe-cutting systems we manufacture.

English

English  Français

Français