Revolutionizing Manufacturing with Cnc Laser Cutting Technology Benefits and Trends in 2023

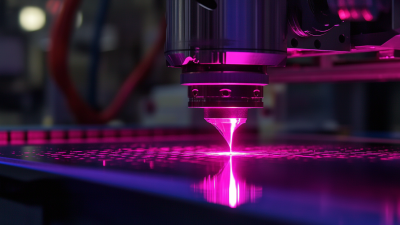

In 2023, the landscape of manufacturing is undergoing a profound transformation, driven by advancements in technology, particularly in the realm of CNC laser cutting. This innovative technique not only enhances precision and efficiency in production processes but also offers a myriad of benefits that cater to the evolving needs of various industries. As manufacturers seek to reduce waste while maximizing output, CNC laser cutting emerges as a pivotal solution that streamlines operations and accelerates turnaround times.

In this article, we will explore the numerous advantages of adopting CNC laser cutting technology, such as improved material utilization, intricate design capabilities, and reduced labor costs. Additionally, we will discuss emerging trends that are shaping the future of manufacturing through this cutting-edge approach, providing valuable insights and practical tips for businesses aiming to revolutionize their production methods.

Understanding CNC Laser Cutting Technology: An Overview

CNC laser cutting technology has emerged as a game-changer in the manufacturing sector, offering precision, speed, and flexibility. The market for CNC laser cutting systems was valued at approximately $545 million in 2022, with projections indicating a robust annual growth rate of 10.25% from 2024 to 2030. This growth is driven by the increasing demand for automation and efficiency across various industries, including automotive and metal fabrication. The adoption of fiber laser technology, in particular, has gained momentum due to its superior cutting speed and quality compared to traditional CO2 lasers.

The impact of the COVID-19 pandemic has also highlighted the need for advanced manufacturing solutions. While some areas experienced disruptions, the shift toward automation and digital transformation accelerated, pushing manufacturers to integrate CNC laser cutting technology into their processes. This trend not only enhances productivity but also addresses labor shortages and safety concerns in factories. As manufacturers adapt to the evolving landscape, the shift towards semi-automated and robotic laser cutting solutions is expected to redefine operational efficiencies in the coming years.

Trends in CNC Laser Cutting Technology for 2023

Key Benefits of CNC Laser Cutting in Modern Manufacturing

CNC laser cutting technology has become a cornerstone in modern manufacturing due to its precision, efficiency, and versatility. The market for CNC laser cutting machines has seen significant growth, fueled by advancements in technology and increasing demand across various sectors. In 2023, key benefits include enhanced adaptability to different materials, which allows manufacturers to produce complex designs with ease and speed. This capability is particularly vital for industries such as automotive, aerospace, and electronics, where precision and customization are paramount.

Emerging Trends in CNC Laser Cutting Technology for 2023

CNC laser cutting technology is undergoing remarkable advancements in 2023, significantly transforming the manufacturing landscape. One of the most prominent trends is the integration of artificial intelligence (AI) for enhanced precision and efficiency. According to a report by MarketsandMarkets, the global CNC laser cutting market is projected to reach $8.2 billion by 2026, driven by the need for high-speed processes and cost-effective solutions. This trend not only reduces waste but also enables manufacturers to achieve unprecedented accuracy in their projects.

In addition to AI, sustainable practices are gaining traction in CNC laser cutting. Companies are increasingly focusing on eco-friendly materials and energy-efficient machines. A study from ResearchAndMarkets indicates that the demand for laser cutting technologies that minimize environmental impact is expected to grow by over 20% annually. Manufacturers are now exploring solutions that not only meet their production needs but also align with their sustainability goals.

Tips: When considering the adoption of CNC laser cutting technology, prioritize suppliers that emphasize innovation and sustainability. Regularly upgrading your machines can also ensure you benefit from the latest improvements in efficiency and quality. Lastly, training staff to leverage these advanced technologies can maximize your investment and streamline operations.

Impacts of CNC Laser Cutting on Industry Efficiency and Precision

CNC laser cutting technology has revolutionized the manufacturing industry by significantly enhancing both efficiency and precision. As industries continue to evolve, the demand for precision machining has surged, leading to substantial growth in the CNC laser cutting market. By 2024, the global market for laser cutting machines is projected to reach impressive valuations, reflecting the rising need for advanced manufacturing solutions. This technology allows for intricate designs and high-quality cuts, reducing material waste and production time, which is critical for maintaining competitiveness in today's fast-paced market.

The impact of CNC laser cutting on industry efficiency cannot be overstated. The technology not only streamlines processes across various sectors, including automotive and aerospace, but also ensures superior accuracy that manual methods simply cannot achieve. With a compound annual growth rate (CAGR) predicted at over 10% for CNC laser processing systems from 2024 to 2030, it’s clear that businesses are increasingly adopting these innovative solutions to enhance their production capabilities. As companies invest in this cutting-edge technology, they position themselves to meet market demands more effectively, thereby driving overall industry growth.

Future Prospects of CNC Laser Cutting in Global Manufacturing Sectors

As we look towards the future of manufacturing, CNC laser cutting technology is set to play a pivotal role in various global manufacturing sectors. The ongoing advancements in this technology promise enhanced precision, efficiency, and customization in production processes. With the CNC machine market projected to grow significantly, from $101.22 billion in 2025 to $195.59 billion by 2032, it becomes evident that industries are increasingly embracing automated solutions to meet rising consumer demands and maintain competitiveness.

In addition to conventional manufacturing, the trends in CNC laser cutting are also adapting to the needs of emerging sectors, including aerospace and defense, where cutting-edge tooling technologies are crucial. The Fiber Laser Market is expected to surge at a CAGR of 11.5% during the forecast period from 2025 to 2035, indicating strong growth for laser-based applications. This trend not only highlights the increased reliance on advanced fabrication techniques but also emphasizes the growing importance of flexibility and innovation in design and production methodologies across manufacturing landscapes.

Revolutionizing Manufacturing with CNC Laser Cutting Technology: Benefits and Trends in 2023

| Dimension | Data |

|---|---|

| Market Size (2023) | $5.5 billion |

| Growth Rate (2022-2027) | +15% CAGR |

| Key Industries Utilizing CNC Laser Cutting | Automotive, Aerospace, Electronics |

| Common Applications | Sheet metal cutting, engraving, and welding |

| Advantages | Precision, speed, minimal waste |

| Emerging Trends | AI integration, automation, and IoT connectivity |

| Future Prospects | Increased adoption across various sectors |

Related Posts

-

Ultimate Checklist for Choosing the Perfect Laser Cutting Machine for Your Business Needs

-

Exploring the Future of Best CNC Laser Cutting in the 2025 Technology Landscape

-

What is a Laser Cutting Machine? Exploring Industry Standards and Trends in Modern Manufacturing

-

Ultimate Checklist for Choosing the Best CNC Cutting Machine for Your Business Needs

-

Exploring the Features and Applications of the Best Industrial Plasma Table for Global Buyers

-

Top 10 CNC Plasma Cutting Table Manufacturers from China at the 137th Canton Fair

English

English  Français

Français