How to Choose the Right Ball Bearing for Your Project?

Choosing the right Ball Bearing for your project is crucial. According to John Smith, a renowned expert in the ball bearing industry, "Selecting the right ball bearing can make or break your project." His insight highlights the importance of understanding the various types of ball bearings and their applications.

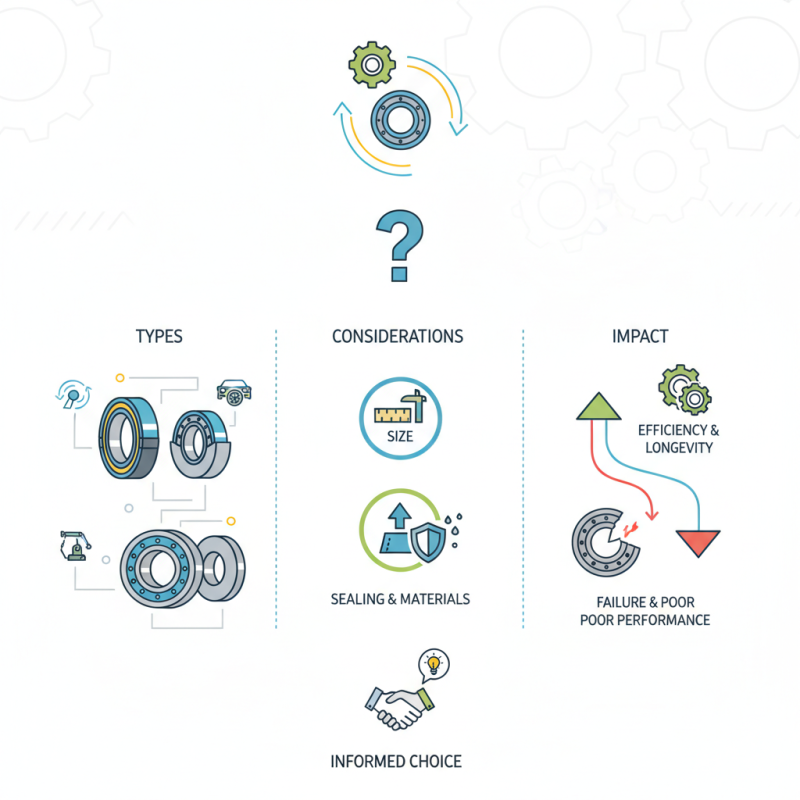

Ball bearings are essential in reducing friction and enhancing the performance of machinery. A well-chosen bearing can improve efficiency significantly. However, with so many options available, it can be overwhelming. You might find yourself questioning if you really need specific features like sealing or materials.

Many overlook the impact of size and load capacity. A mismatch can result in premature failure or less than optimal performance. Reflecting on your project's unique demands can guide your choice. Choosing a ball bearing is not just a technical decision; it involves careful consideration of various factors. Understanding these nuances will ultimately lead to better outcomes.

Understanding the Basics of Ball Bearings and Their Functionality

Ball bearings are crucial components in many machines. They facilitate smooth movement between moving parts. Understanding how they work can help you select the right type for any project.

A ball bearing consists of balls that reduce friction. They sit between two metal rings. This design allows for better load distribution and smoother rotations. In different applications, the size and quality of these balls can vary significantly. Choosing the wrong size or material can lead to inefficiency or failure.

Tips: Always consider the load requirements of your project. Assess the environment where the bearing will operate. High temperatures or moisture can affect performance. A small oversight can lead to larger issues later. Testing might be necessary to ensure compatibility.

Another factor is the bearing's speed rating. Some bear high speeds better than others. However, not all applications require high-speed bearings. Sometimes, a standard option may suffice. Remember, cost does not always equate to quality.

Identifying the Key Factors for Selecting Ball Bearings

When selecting the right ball bearing for your project, there are several key factors to consider. Start with the load capacity. How much weight will the bearing need to support? Understanding this helps prevent premature wear or failure. Different applications might demand different load ratings. Be sure to choose a bearing that can handle the expected stress.

Next, consider the speed factor. What is the maximum operational speed required? Bearings designed for high speeds often have specific characteristics, such as lower friction. This ensures durability and efficiency. Some projects may overlook this detail, leading to overheating and potential damage.

Additionally, think about the environment in which the bearing will be used. Will it face dust, moisture, or extreme temperatures? Selecting a bearing with appropriate seals or materials is crucial for longevity. It’s easy to underestimate these conditions. Ignoring them could lead to costly repairs. Pay attention to these details, as they can significantly affect performance and lifespan.

Ball Bearing Selection Factors

Exploring Different Types of Ball Bearings and Their Applications

When selecting a ball bearing, understanding the various types is crucial. Each bearing type serves specific functions. Deep groove ball bearings, for example, are versatile. They can handle radial and axial loads. According to a recent report from MarketsandMarkets, this type accounts for over 40% of the ball bearing market. Their adaptability makes them popular in industries ranging from automotive to robotics.

Another type, angular contact ball bearings, is designed for radial loads and axial loads in one direction. These bearings optimize performance in high-speed applications. They are essential in sectors like aerospace and machine tools. A study from Research and Markets indicated that the demand for angular contact bearings is expected to grow by 5% annually through 2027. This trend suggests technological advancements are increasing their applications.

However, selecting the right bearing often involves trial and error. Not all projects benefit from the latest technology. Some projects may require standard solutions to be cost-effective. Ignoring the specific needs of your application can lead to inefficiencies. Conducting thorough research and consulting industry experts can mitigate these risks. Remember, the right choice enhances longevity and performance, so weigh the options carefully.

Assessing Load Capacity and Speed Requirements

When choosing a ball bearing, assessing load capacity and speed requirements is crucial. Load capacity refers to the maximum weight a bearing can support. For many applications, this is paramount. According to industry reports, a bearing's rated load capacity directly impacts its lifespan and performance. Often, bearing failures arise from exceeding these limits. Therefore, knowing the weight and speed involved in your project helps narrow down your options.

Consider the speed ratings of ball bearings too. Speed ratings indicate how fast a bearing can operate without failure. High-speed applications require bearings designed for low friction and heat generation. A survey by the International Journal of Engineering reports that improperly matched RPM (revolutions per minute) can lead to premature wear. A faster bearing isn’t always better; you need the right balance for your project.

Tips: Always calculate the expected load and speed beforehand. Avoid making assumptions about performance. It can be misleading. Regularly check for wear and lifespan, ensuring that your choice aligns with actual project needs. Be open to reevaluating your choices as data evolves. Your project's success depends on accurate specifications.

Evaluating Material Options for Durability and Performance

When selecting ball bearings, understanding material options is vital for achieving durability and performance. Stainless steel is popular due to its corrosion resistance. It is ideal for environments with moisture or chemicals. However, stainless steel can be heavier, affecting the overall weight of your project.

Plastic bearings offer a lightweight alternative. They can be effective in lighter applications, especially where lubrication is a concern. However, they may not handle heavy loads as well. Be cautious about using them in high-stress scenarios.

**Tip:** Consider the operating temperature of your project. Materials perform differently at varying temperatures.

Another option is ceramic bearings. They are excellent in high-performance applications, offering reduced friction. Yet, they can be brittle, requiring careful handling. Think about the trade-offs when choosing.

**Tip:** Test different materials in your designs to see what performs best. Adjustments can lead to significant improvements.

How to Choose the Right Ball Bearing for Your Project? - Evaluating Material Options for Durability and Performance

| Material Type | Corrosion Resistance | Load Capacity | Operational Temperature Range | Typical Applications |

|---|---|---|---|---|

| Stainless Steel | High | Moderate | -100°F to 400°F | Food processing, medical |

| Chrome Steel | Moderate | High | -20°F to 200°F | Automotive, industrial machinery |

| Plastic | Low | Low | -40°F to 180°F | Lightweight applications, home appliances |

| Ceramic | Very High | Very High | -400°F to 600°F | Aerospace, high-performance applications |

| Bronze | Moderate | Moderate | -40°F to 300°F | Marine, electrical applications |

English

English  Français

Français