7 Amazing Benefits of Cnc Cutting Tables That Transform Your Manufacturing Process

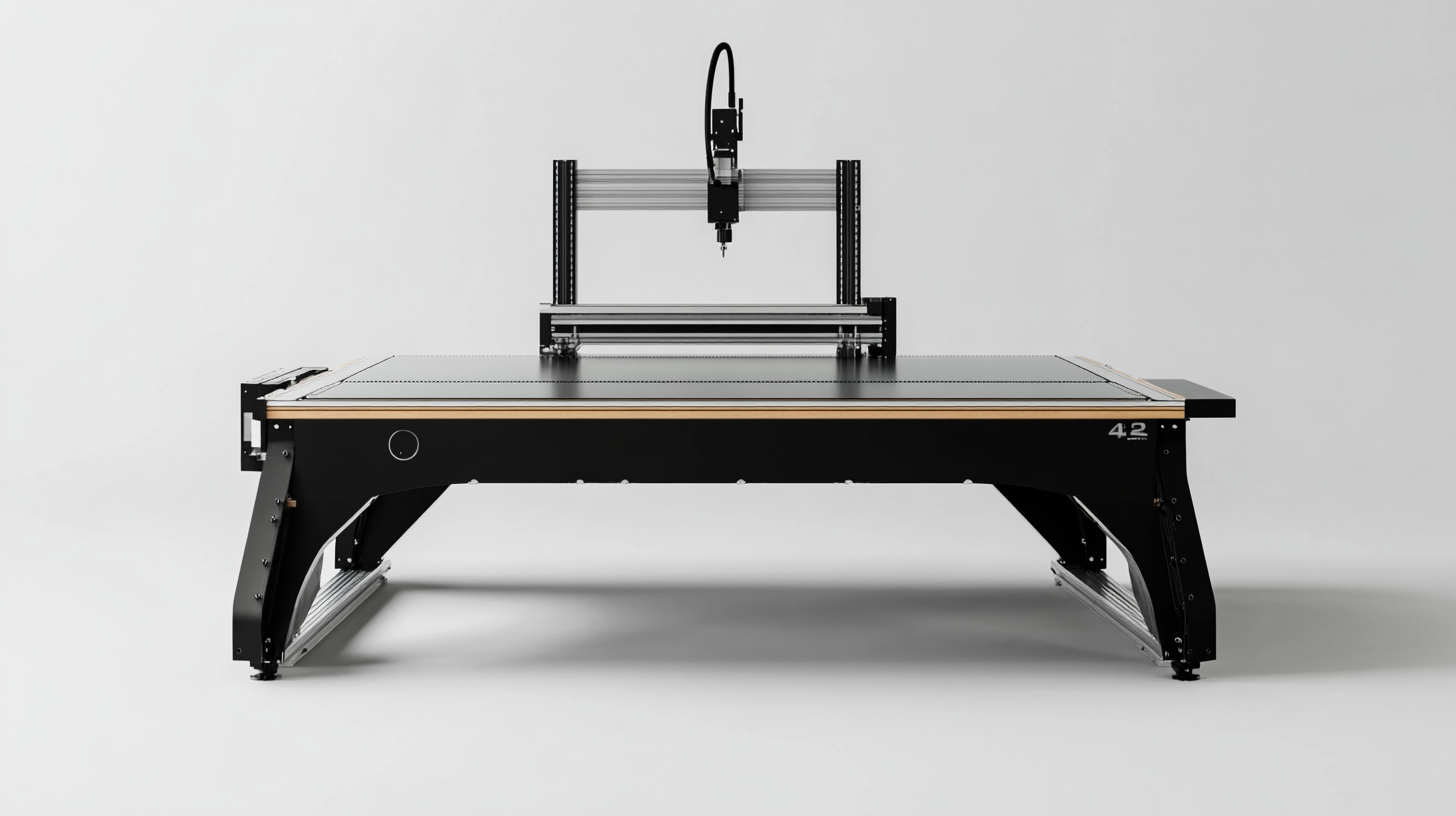

In today's competitive manufacturing landscape, efficiency and precision are paramount. One innovative solution that has revolutionized the industry is the CNC Cutting Table. This advanced technology not only enhances the production process but also opens up a realm of possibilities for manufacturers looking to elevate their operations. The ability to automate cutting tasks minimizes human error and maximizes output, allowing businesses to meet high demands with ease. Furthermore, CNC Cutting Tables offer versatility across various materials, making them a valuable asset for diverse industries. In this blog, we will explore seven amazing benefits of CNC Cutting Tables that can significantly transform your manufacturing process, enhancing both productivity and quality. Embracing this technology is no longer a luxury but a necessity for manufacturers aiming to thrive in a fast-paced market.

Benefits of Enhanced Precision and Accuracy with CNC Cutting Tables

CNC cutting tables have revolutionized the manufacturing sector by enhancing precision and accuracy in various applications. Unlike traditional cutting methods, CNC technology allows for intricate designs and repeatable results with minimal human intervention. This level of precision is crucial for industries where tolerances are tight and quality control is paramount. With automated feedback systems, CNC machines can make real-time adjustments, ensuring that the finished product consistently meets exact specifications.

The benefits extend beyond accuracy; CNC cutting tables also boost efficiency. By automating the cutting process, manufacturers can significantly reduce production time and minimize material waste. This not only lowers costs but also enhances the overall workflow. Operators can input designs digitally, allowing for quick adjustments and iterations without the need for extensive manual rework. As a result, businesses can respond more swiftly to market demands while maintaining high standards of quality and precision.

7 Amazing Benefits of Cnc Cutting Tables That Transform Your Manufacturing Process

| Benefit | Description |

|---|---|

| Precision Cutting | CNC cutting tables provide enhanced precision, allowing for intricate designs and exact measurements. |

| Increased Productivity | Automation of cutting processes reduces manual labor and increases manufacturing speed. |

| Cost Efficiency | Minimizes material waste through precise cuts, optimizing overall production costs. |

| Flexibility | CNC cutting tables can work with various materials, making them suitable for diverse applications. |

| Enhanced Safety | Automated systems reduce the risk of accidents associated with manual cutting methods. |

| Design Reproducibility | CNC technology ensures consistency in replicating designs across multiple projects. |

| Fast Prototyping | Rapid adjustments and iterations on designs can be made, accelerating the prototyping phase. |

Boosting Production Speed: How CNC Technology Streamlines Workflow

CNC technology is revolutionizing the manufacturing landscape by significantly enhancing production speed and workflow efficiency. According to a report by the International Data Corporation (IDC), companies that implement CNC machinery can experience a time reduction in production cycles by up to 30%. This acceleration is primarily due to the automation capabilities of CNC cutting tables, which minimize manual intervention, thus reducing the likelihood of human error and streamlining operations.

By integrating CNC cutting tables into their workflows, manufacturers are able to optimize resource allocation and facilitate rapid prototyping. A study conducted by the Society of Manufacturing Engineers (SME) indicates that businesses utilizing CNC systems reported a 50% increase in production throughput. The precision of CNC technology allows for intricate designs and high-quality outputs at speeds unattainable by traditional methods. This enhanced productivity not only meets the growing demands of the market but also supports the overall sustainability efforts within the manufacturing sector by reducing waste and improving material efficiency.

Ultimately, the adoption of CNC cutting tables is not just a technological upgrade; it represents a strategic advantage in a fiercely competitive environment, allowing manufacturers to respond swiftly to market changes and customer needs.

7 Amazing Benefits of CNC Cutting Tables

This pie chart illustrates the amazing benefits of CNC cutting tables that enhance production speed and streamline workflow in the manufacturing process.

Cost Efficiency: Reducing Material Waste Through CNC Cutting

CNC cutting tables are becoming a cornerstone for manufacturing operations aiming to reduce costs and optimize material usage. One of the most significant benefits is their ability to minimize material waste. Traditional cutting methods often leave behind excess material, increasing costs and negatively impacting sustainability. In contrast, CNC cutting tables employ advanced algorithms to ensure precise measurements and cuts, allowing manufacturers to utilize materials more efficiently. This shift not only streamlines production processes but also aligns with broader sustainability goals, as companies are increasingly held accountable for their environmental impact.

The integration of AI-driven CNC machining further enhances cost efficiency. By utilizing artificial intelligence, manufacturers can predict potential issues in the cutting process and make necessary adjustments in real-time. This capability not only sharpens precision but also eliminates costly errors and rework, giving businesses a competitive edge. As the laser cutting machines market continues to expand, propelled by advancements in technology and increasing demand for high-precision manufacturing, companies that invest in CNC cutting tables will likely see transformative changes in their operational efficiency and cost management strategies.

Cost Efficiency: Reducing Material Waste Through CNC Cutting

This chart illustrates the material waste reduction benefits of using CNC cutting tables compared to traditional manufacturing methods. The data represents the percentage of material saved over different manufacturing volumes.

Versatility and Flexibility: Adapting CNC Tables for Various Materials

CNC cutting tables are revolutionizing the manufacturing process by offering remarkable versatility and flexibility in material handling. These advanced machines can accommodate a wide range of materials, including wood, metal, plastic, and composites, making them suitable for diverse applications. With the ability to easily switch between different tools and settings, manufacturers can customize their cutting processes to meet specific project requirements, leading to increased efficiency and reduced downtime. This adaptability not only streamlines production but also enhances the ability to produce complex shapes and designs that would be challenging using traditional methods.

Moreover, the flexibility of CNC cutting tables extends beyond just material types. They can be programmed to execute intricate cuts with precision, allowing for intricate designs and patterns that cater to various industries. This capability is particularly beneficial for businesses that require quick turnarounds and tailored solutions, such as custom furniture fabrication or intricate signage production. By leveraging the versatility of CNC cutting tables, manufacturers can respond swiftly to market demands, innovate their offerings, and ultimately transform their overall production workflow.

Improved Safety and Working Conditions in Manufacturing Environments

The integration of CNC cutting tables in manufacturing environments significantly enhances safety and working conditions for employees. One of the primary advantages of these advanced machines is their precision. By automating cutting processes, CNC tables reduce the risk of human error, which can lead to dangerous accidents. Workers can focus on monitoring the operation rather than performing repetitive tasks, minimizing their exposure to potential hazards associated with manual cutting methods.

Moreover, CNC cutting tables are designed with safety features that protect workers from common risks. Enclosed cutting areas, emergency stops, and advanced controls ensure that operators can work confidently without the fear of sudden accidents. This increased safety not only promotes a healthier work environment but also boosts morale among employees, knowing they are operating within a system that prioritizes their well-being. With better safety protocols in place, manufacturers can significantly reduce workplace injuries and associated downtime, leading to a more productive and positive work culture.

English

English  Français

Français